AI-based identification of CO₂ values

In order to achieve the goals of the Paris Climate Agreement, we need to rapidly reduce CO₂ emissions worldwide. A significant proportion is generated by industrial processes whose carbon footprints are difficult to calculate. This affects the transparency and comparability of the CO₂ balance of products. The Green-AI Hub Mittelstand's pilot project with CircularTree is developing an AI solution that supports the calculation of the carbon footprint, achieves better results faster, increases transparency and makes the procedure scalable. This opens up a wide range of new possibilities for decarbonising products.

Supporting decarbonisation

CircularTree, a company founded in Berlin in 2018, is committed to supporting companies in the decarbonisation of their products and supply chains. Their SaaS platform ‘CarbonBlock’ enables the calculation and exchange of the carbon footprints along the supply chain. CarbonBlock is interoperable, meaning it can interact with all relevant exchange standards, and it promotes decarbonisation through collaboration with suppliers.

Challenge of manual CO₂ calculation

The manual CO₂ calculation of product components based on a bill of materials requires considerable human and time resources. Information on individual components would first have to be searched online and then assigned to the correct processes in a life cycle assessment (LCA) database (which contains industry average values). This requires extensive material knowledge, experience in dealing with various LCA databases, and expertise in CO₂ life cycle analyses. For companies with many purchased components, this represents a significant financial burden.

Resource efficiency through automated CO₂ footprint calculation

In the Green-AI Hub pilot project, an entity mapping (classification) is created. This allows CircularTree's customers to easily identify the product components to calculate their carbon footprint. To achieve this goal, the following steps are implemented:

- Analysis and definition of requirements

- Data acquisition

- Use of natural language processing technologies and classification techniques to identify the most appropriate classes or labels for each product or product component

- Training a model based on BERT or Transformers using zero-shot or few-shot learning techniques, as well as the possibility of using generative models, such as ChatGPT, to perform the classification

- Implementation of an entity mapping visualisation

More transparency in the value chain

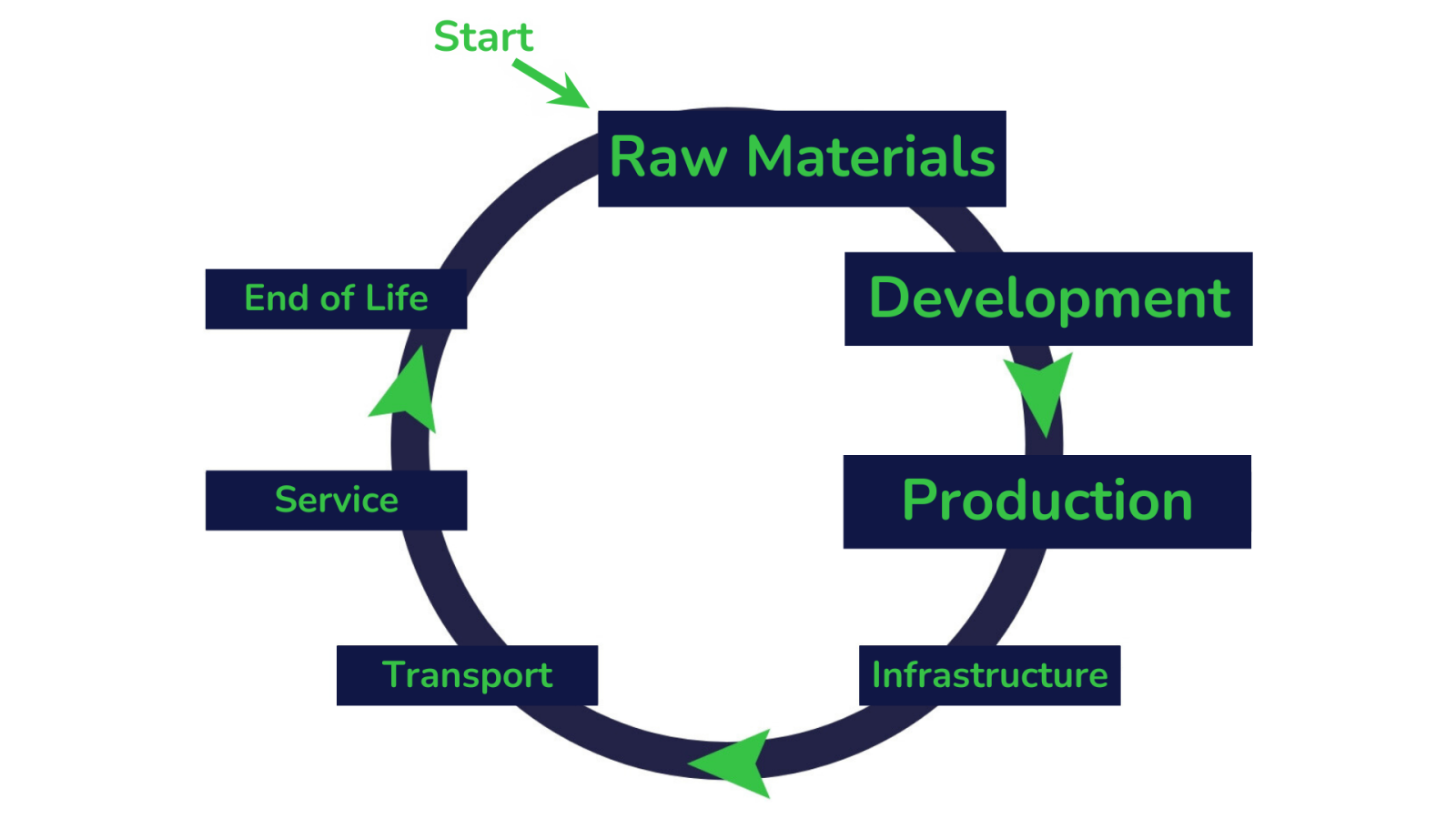

The AI pilot project addresses various stages of the value chain. Initially, it is about the transparency of the CO₂ footprint of components and raw materials. This increased transparency, in turn, aids in selecting appropriate components and raw materials to reduce the overall carbon footprint. In production, the increased transparency can ultimately enable agreements with suppliers to reduce supply chain emissions.

Increasing efficiency through automation

Based on the acquired data, the carbon footprint of products can be reduced, for example by using recycled materials. This financial efficiency gain is also relevant for any company that needs to classify product components by their name. Automation also reduces the amount of time and labour which CircularTree previously had to invest in manually classifying the CO₂ emissions of the numerous components for each product.

Presentation of the Green-AI Hub pilot project “AI-based identification of CO₂ values“ - 8:06 min.

-

Gunther Walden, CircularTree GmbH

- Julián Moreno Schneider, German Research Center for Artificial Intelligence GmbH

Technology

AI capability: analysing

AI model: entity mapping (classification)

Value creation

Phase: production

Aim of AI: Automated classification of the CO₂ footprint

Resource efficiency

Efficiency gains in time, personnel, and financial resources

Possible reduction of the CO₂ footprint of products through the use of recycled materials