AI-based configuration of heating systems

Our pilot project at KÜBLER GmbH uses an AI-based system configurator to optimise the construction of heating systems for halls and warehouses.

Construction of hall heating systems

KÜBLER builds heating systems designed to operate with high energy efficiency in large halls. The product range includes variants with additional features such as lighting, cooling, ventilation, and thermally supported heating. The latest generation of infrared heaters (FUTURA and MAXIMA E-Hybrid) can use a variety of energy sources, including biogas, liquefied gas, hydrogen components, natural gas, or electricity. Users can switch between these energy sources based on cost or availability.

Individual configuration of systems

To ensure efficient heating system utilisation, 3D models of the halls are employed during the planning phase. Materials made of metals, plastics, cardboard, glass fibres and composite materials are used in the production process. KÜBLER offers various individual solutions for configuration, planning, and price quotation systems, such as calculating the heating load and selecting the type and number of units. System information, such as CAD plans and operational data, is available in multiple formats and locations.

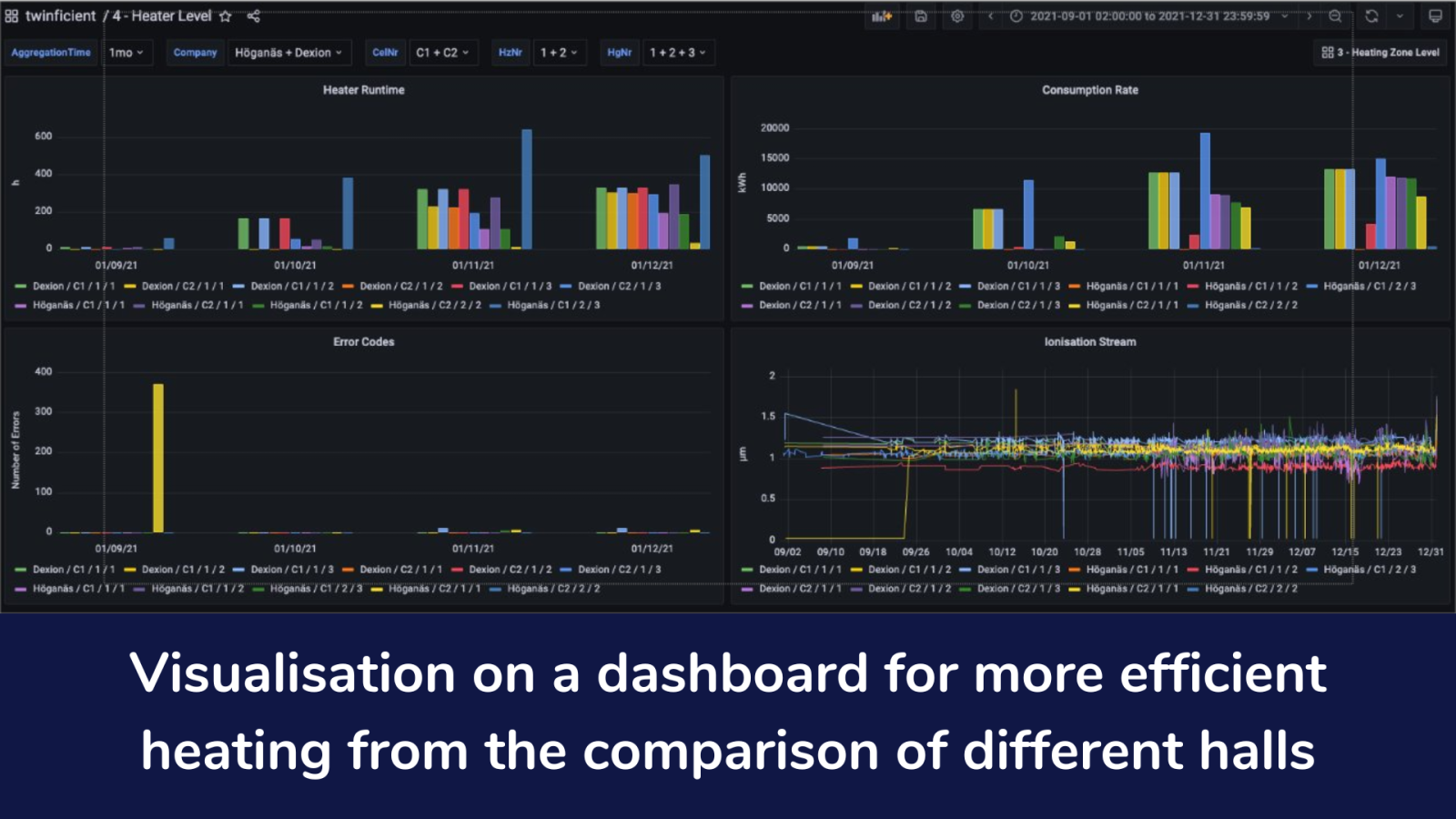

Digital twin with visual simulation

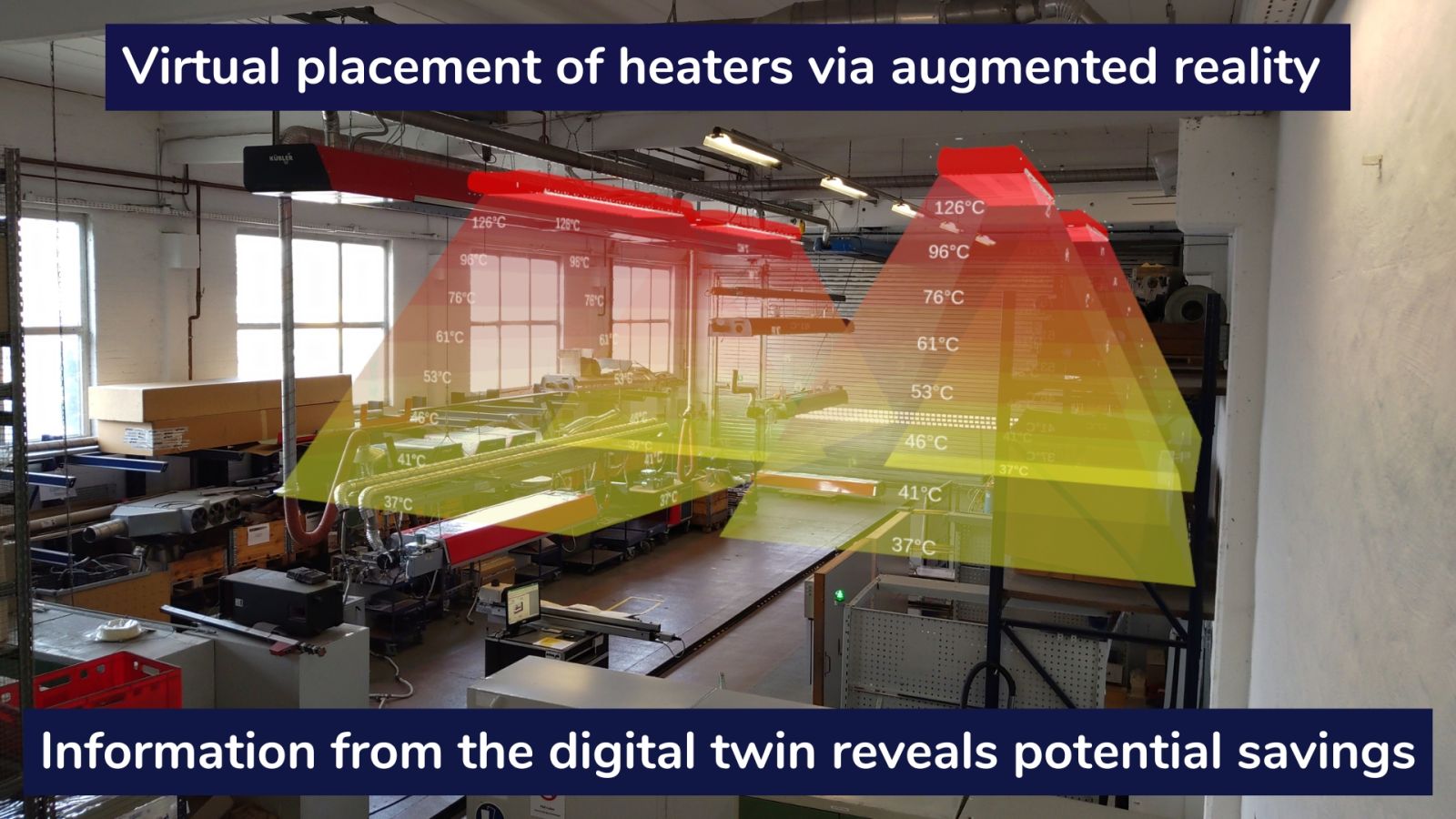

For the first time, these different information sources will be integrated through a digital twin by the Green-AI Hub Mittelstand pilot project. The digital twin analyses the data, which enables enormous savings potential for future systems by revealing oversizing and by optimising the technical coordination of individual system components.

The digital twin is supplemented by mixed reality glasses which visualise the system. This feature allows for pre-installation visual checks, for example, in an assembly hall, to determine the optimal placement of heating systems based on empirical data and visual feedback. Adjustments can be made during the process if needed. Visual simulations can reveal direct savings potential, such as the need for fewer or smaller systems than initially assumed. Indirect savings potential can also be identified, such as the possibility of additional appliances that could enable more efficient operation, extending the appliances' lifespan, and promoting sustainability.

AI as a data interface

The digital twin allows for the conservation of resources at various stages. It includes a digital product pass listing recyclable components, contributing to a circular economy. Savings can also be achieved during operation. Simulation and mixed reality visualisation scenarios can be used to reduce the number or size of systems used, avoid peak operation, and reduce overall energy consumption – including electricity and gas.

The pilot project considers hall heating systems in an overall context (Smart Living, Smart City, Industry 4.0, etc.) and integrates other sensors and information sources (e.g. hall activity) into the analysis (shared data space). This enables more accurate usage pattern assessments and holistic predictions. A standardised data interface within the digital twin consolidates all critical operational data.

Optimised system configuration saves resources

AI not only improves the company's resource efficiency but also enhances the resource efficiency of KÜBLER's customers who use their infrared heaters. This includes benefits for already installed heaters, such as adapted maintenance schedules to prevent failures, costly repairs, travel expenses, and consequential damage. Improved planning and dimensioning of new halls enable better future planning based on collected usage data. In addition, AI and the digital twin of the heating systems are continuously developed and refined, leading to savings in materials, energy, and CO2 emissions.

Via the link you will find an RTL report in the Nachtjournal from 31.05.2024 (German from 27:35 onwards) on the Green-AI Hub Mittelstand and hall heating systems from KÜBLER.

Presentation of the Green-AI Hub pilot project “AI-based configuration of heating systems” - 14:04 min.

- Jens Findeisen, KÜBLER GmbH

- Sönke Knoch, German Research Center for Artificial Intelligence GmbH

Technology

AI capability: recommendation for action and visualisation

AI model: digital twin

Value creation

Phase: production

Aim of AI: optimised use and configuration of heating systems

Resource efficiency

Savings in the primary energy source for the customer

Material savings during construction

Longer service life of components

Company

Industry: energy-saving industrial and commercial heating systems

Approx. 130 employees

KÜBLER GmbH Energiesparende Hallenheizungen